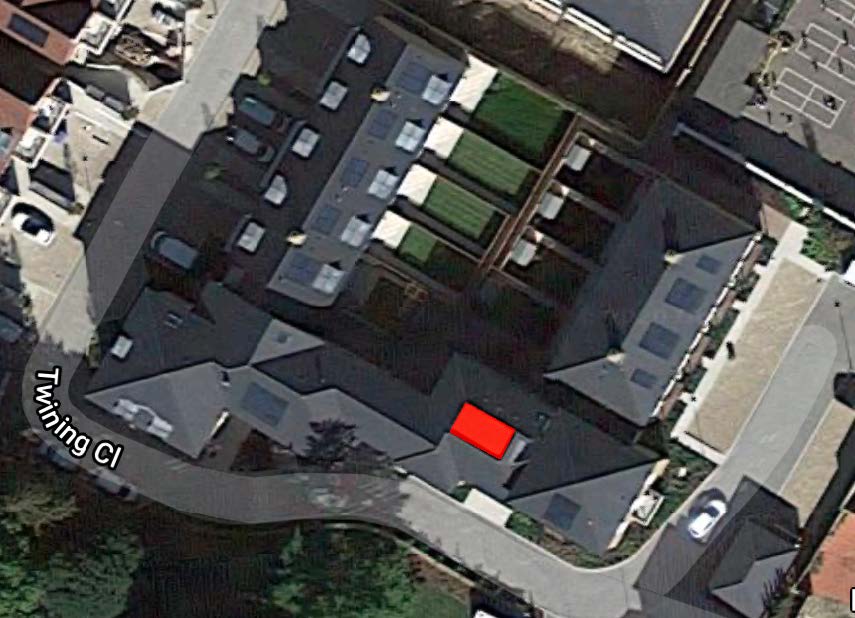

Location: Twinning Close, Tunbridge Wells, Kent, TN4 8FJ

Roof Tested: Apartment Block A/B Roofs

Dates Tested: 26/05/20

Roof Detail: Hot-Melt Waterproofing Membrane

Prepared for: French Roofing

Prepared by: Christian Novak

26 May 2020

Ref: 239843-TWT

INTRODUCTION

Objective

Objective

This report is prepared for the purpose of documenting results of the non-destructive electronic leak test on the installed waterproofing membrane. The electronic leak detection survey allows our trained operative to pinpoint any defects in the waterproofing membrane for repairs to be made and prevent water ingress.

Goals

Goals

Electronic Leak Detection along with our extensive experience provides us the ability to locate defects in a waterproofing membrane that may allow water ingress via mechanical damage, installation defects or failure of the waterproofing product.

Method

Method

Working on the premise that a waterproofing membrane is non-conductive, or partially non-conductive, it will act as an electronic insulator to the conductive materials below. When an electronic current is applied either directly to the dry membrane (dry test), or via moisture on a wet membrane (wet test), any defect will allow the electronic current to discharge to earth, or a discharge to the lower dielectric strength of the material below.

RESULT

Test Result

Test Result

There were no areas isolated from the testing procedure. The site survey identified 0 pathways where water may enter into the building construction.

| Description | Quantity |

| Mechanical Penetration | 0 |

| Installation Defect | 0 |

| Membrane Failure | 0 |

| Other | 0 |

| Total | 0 |

RESULT

Test Result

Test Result

There were no areas isolated from the testing procedure. The site survey identified 0 pathways where water may enter into the building construction.

| Description | Quantity |

| Mechanical Penetration | 0 |

| Installation Defect | 0 |

| Membrane Failure | 0 |

| Other | 0 |

| Total | 0 |

CONCLUSION

The survey identified 0 pathways where water may enter into the building construction.

METHOD STATEMENT

Requirements

Requirements

Warm systems whereby the insulation is below the waterproofing membrane, may require a period of weathering before testing is carried out to allow water ingress into defects.

Inverted systems whereby the waterproofing membrane is applied directly ply wood, a dry test is the preferred method as the ply has a lower dielectric strength than that of the membrane. If it is not possible for a dry test, we will require access to the wet ply below the waterproofing membrane to connect the wet test pulse generator to “earth”.

All excessive ponding water must be removed from the test area prior to site inspection.

Exclusions

Exclusions

An up-stand can have many different types of build-up. Some of these types cannot be wet tested. Due to unknown weather conditions, it is our policy that up-stands are excluded from the testing procedure unless specifically requested. If this request is made, we will require a visit on a dry day or have the areas covered until the test is to be carried out.

Membranes of a conductive nature cannot be tested unless the dielectric strength of the material it is applied to is greater than the membrane required to be tested. Membranes such as EPDM or membranes with a metallic solar reflective paint cannot be tested by electronic testing. We do however provide other means of leak detection on these types of membrane.

Testing Procedures

Testing Procedures

Each testing procedure has benefits depending on the type of membrane, type of material used below the membrane and current weather conditions. We will only use the correct and most accurate means of testing.